What if your digital prints could do more than just deliver good quality?

When you think about digital printing, you probably immediately think of high-quality images, affordable short runs, fast turnaround times, inline finishing and a multitude of print media. Sure, we’ve been using the benefits of digital printing for a long time. But what if your digital prints could do more than just deliver good quality? What if they could beautify prints, prevent counterfeiting, enhance appearance, attract attention, and even save you time and money?

For years, printers have relied on varnishes to achieve that classic glossy effect. It’s reliable, familiar, and does the job. However, it involves coatings that often come at a high price, and making spots or patterns takes time and requires more operations and consumables. In addition, the increasingly frequent shortening of print runs and coatings to printed pages can become expensive and time-consuming.

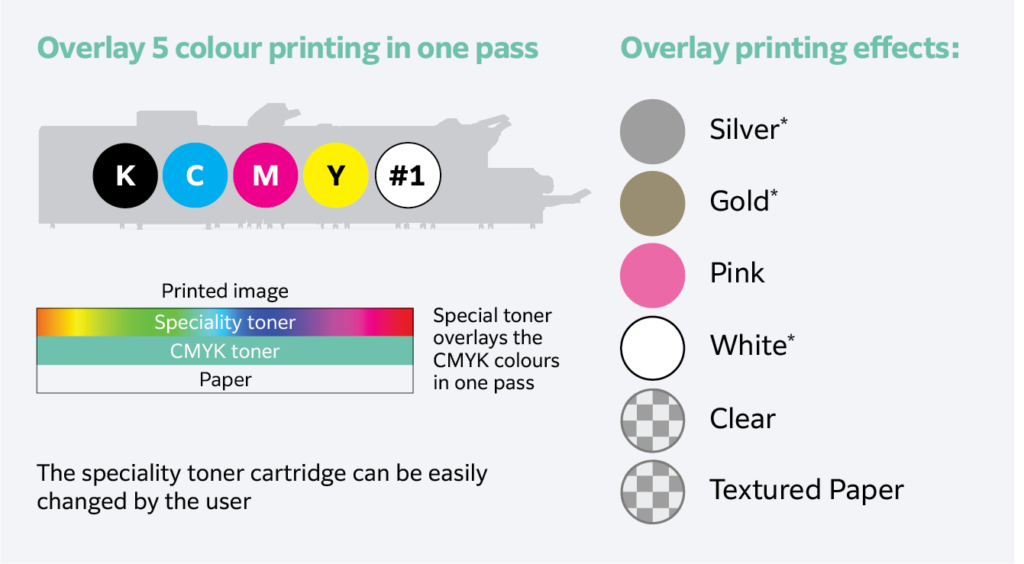

Fujifilm’s new upper mid-range and mid-range 5-colour toner devices, the Revoria EC2100S and SC285S, offer a more versatile approach. These machines incorporate five print stations that integrate a special colour, such as glossy transparent toner, to print at the same time as traditional CMYK colours. Whether you’re a commercial printer, a luxury brand, or a company looking to add value to your documents, the Revoria presses’ transparent toner offers a smarter way to print that opens up a whole new world of printing possibilities.

Beyond traditional varnish

Traditional varnishes are glossy and protect from fingerprints and scuffing, but inhalation of their fumes can be toxic, requiring specialised facilities and expensive equipment. Additionally, creating spot varnishes and patterns also complicates the process and increases costs. So much so that coatings are often contracted out to external companies, making delivery of the final product more expensive and time-consuming.

The Revoria EC2100S and SC285S use transparent toner – a fifth colour layer – to create specific shine effects directly and in a single pass, together with CMYK colours. Effects such as reserves (areas left unprinted by the transparent toner to create contrast) and screens can be produced easily and with extreme precision, even on fine lines and text. Gloss toner can also be mixed with CMYK colours, creating glossy colour effects integrated into the print.

Spot coating: shine exactly where you want it

Clear toner stands out in spot coating, highlighting specific areas rather than the entire page. If you need a logo to stand out, or if you need to draw attention to a specific product in a photograph, transparent toner can do this easily and cost-effectively. The application is done in a single pass at the same time as CMYK printing.

Security applications

Beyond aesthetics, clear toner also offers security features. You can create watermarks or background patterns, which can even be customised and unique to each print, that are not easily copied or scanned. This makes it easy to detect counterfeit documents, protecting your business and your customers. For lottery tickets, event passes, or important certificates, transparent toner adds a layer of security without the need for complex processes or additional materials.

Putting clear toner in the mix

Normally, transparent toner (or varnish) is added as an overlay. During the standard process, the colours- cyan, magenta, yellow, and black (CMYK) – are printed and then the clear toner is placed on top. But the Revoria EC2100S and SC285S presses offer a distinctive advantage. They can mix clear toner with other colours during the printing process in a single pass.

Previewing without printing

One of the smartest features of the Revoria EC2100S and SC285S is the ability to preview speciality colours without printing, a feature called Spot Colour Preview.

With this function, you can simulate how your speciality toner (in this case, a gloss effect) will affect the final appearance of your document when special colours are added to the CMYK colours. The ability to preview this on screen reduces the need and frequency of test prints. The preview even simulates what it will look like when the paper type is changed, including coated, offset, rough-gloss, embossed and pearlescent papers.

This functionality is offered through two integrated tools: Revoria Flow, Fujifilm’s DFE print server, and Adobe’s Speciality Colour Quick Viewer plug-in for designers to remotely view the output of their speciality colour designs. The result is reduced waste, time savings, and perfect results from the first print.

Adding volume and texture

With the Revoria EC2100S and SC285S, you’re not limited to flat finishes. These machines allow you to apply up to seven layers of clear toner, creating a tactile experience. You can feed the sheet back into the machine, adding more transparent toner with each pass. Each layer adds a little more height, creating a small relief effect. This capability is ideal for enhancing designs with a 3D display, such as fashion, art, textures or embossed patterns and logos. Customers love this sense of volume or the feel of embossed prints, and the procedure is extremely simple.

A safer option

While traditional varnishes can contain chemicals that produce a noticeable odour and may require specific ventilation, transparent toner shares the safety characteristics of modern digital printing toners. This offers a more comfortable working environment and simplifies setup, as it avoids the ventilation considerations often associated with traditional varnishes.

When to use transparent toner

Transparent toner is perfect for companies that want their printed materials to stand out. Luxury goods, commercial products and marketing materials all benefit from its effects. For product marketing, clear toner can highlight key features, draw attention to important information and add sophistication.

It’s equally valuable for security applications: even tickets, lottery slips, and official documents gain protection against forgery. Even small details such as glossing a signature or adding personalisation, such as consecutive numbers to each print, are possible because digital gloss printing is precise and versatile.

Print sample request

See the quality you could achieve with a 5UPER COLOUR® press

Request a sample

Thank you for your enquiry, someone will be in contact soon.

The Revoria Range

Fujifilm’s Revoria range includes several digital production printers designed for professional print environments. These machines are engineered with versatility in mind, and offer printing capabilities of up to six colours – CMYK plus speciality colours such as clear, gold, silver, and pink toner. Replacing one special colour with another can be done by the machine operator in just a few minutes and adjustments are made automatically without the need for cleaning or proofing prints.

What makes these machines truly remarkable is their integrated approach to expanding the possibilities of printing. Instead of requiring additional equipment or post-processing steps, Revoria printers incorporate speciality colour management directly into your workflow to embellish, extend the traditional CMYK colour gamut or expand the number of jobs that can be produced on demand with documents that previously could not be produced with toner technology.

The Revoria EC2100S and the Revoria SC285S presses make this technology accessible and easy to implement, offering printers and designers new ways to add value to their work without complex processes or expensive equipment. They enable companies to innovate, whether they’re creating high-end marketing materials, achieving colours not previously accessible with CMYK alone, or exploring new creative possibilities.

Thinking beyond the basic glossy finish has never been more accessible, more versatile, or more impactful than with Fujifilm’s Revoria range of print-on-demand presses.