A Fujifilm possui uma longa reputação em inovação tecnológica, e sua transformação no mercado de impressão sob demanda (POD) é uma continuação desse legado. A trajetória da Fujifilm no mercado europeu de POD começou em 2021, com o lançamento gradual da marca Revoria. Desde então, a linha tem desfrutado de um sucesso notável, construída com base em uma tradição de 60 anos em tecnologia de toner seco e um compromisso com a inovação contínua.

A impressora Revoria Press PC1120 de 6 cores, o principal produto da linha Revoria, já deixou um marco, permitindo que empresas de impressão ofereçam soluções criativas inovadoras e agreguem valor significativo aos clientes, graças ao seu desempenho premiado e à capacidade de imprimir cores especiais sob demanda.

Agora, as novas impressoras de médio porte da linha Revoria, apresentadas na drupa 2024 e lançadas comercialmente em dezembro de 2024, ampliam o acesso à impressão de valor agregado com canais de cores adicionais. Com o lançamento das impressoras Revoria EC2100 e SC285, a Fujifilm agora oferece impressoras de produção de médio porte que oferecem impressão em quatro cores excepcional e de alta qualidade, adequada para a mais ampla gama de aplicações, com eficiência e velocidade inovadoras. Essas impressoras são totalmente atualizáveis em campo para os modelos "S", que se distinguem pela capacidade de incorporar toners especiais em um quinto canal de cores, como toner de papel transparente, rosa ou texturizado, proporcionando possibilidades criativas aprimoradas.

O EC2100S e o SC285S descobertos

No centro desses dispositivos está um número extraordinário de inovações tecnológicas Fujifilm. Entre elas, mais de vinte novas patentes exclusivas para esses dispositivos e mais de 200 patentes Fujifilm no total, incluindo inovações para aumentar a qualidade, a produtividade, a eficiência e a sustentabilidade.

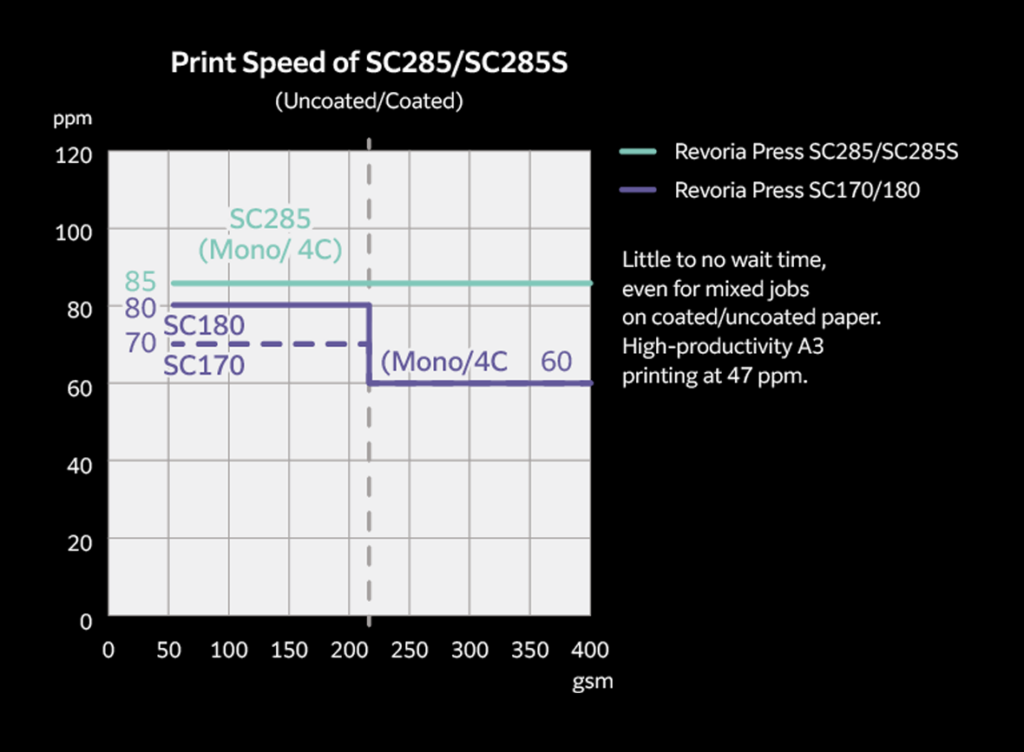

À primeira vista, a Revoria EC2100S e a SC285S podem parecer muito semelhantes, mas, embora compartilhem as tecnologias avançadas e essenciais da Fujifilm, atendem a diferentes necessidades de produção. A Revoria EC2100S foi projetada com foco na produtividade, operando a uma velocidade de impressão de até 100 páginas por minuto (ppm) em A4, tornando-a adequada para ambientes com alto volume de impressão. A SC285S, com uma velocidade de impressão ligeiramente inferior de 85 ppm em A4, é otimizada para empresas que exigem qualidade de impressão premium com maior versatilidade no manuseio de mídias, em volumes ligeiramente menores.

5UPER COLOUR

Sem dúvida, a principal vantagem das impressoras EC2100S e SC285S é a capacidade de imprimir com cinco cores em uma única passagem, o que a Fujifilm denomina '5UPER COLOUR'. Atualmente, impressoras com essa capacidade estão disponíveis apenas no segmento de alto padrão do mercado.

Este benefício adicional oferece a possibilidade de imprimir com toner de papel transparente, rosa ou texturizado, além do CMYK, permitindo uma gama maior de possibilidades criativas, beneficiando designers, gráficas comerciais e empresas que buscam expandir seus serviços de impressão. Ideal para embalagens de luxo, materiais de marketing e álbuns de fotos, onde é necessário replicar tons de pele de altíssima qualidade, produzir cores mais profundas e ricas, imprimir com efeito de verniz ou imprimir em papel texturizado ou gofrado mais difícil.

Ao contrário dos modelos concorrentes, que exigem longos períodos de inatividade para trocas de toner especial, as impressoras Fujifilm permitem a troca rápida de toner em menos de dez minutos. Isso reduz significativamente as interrupções na produção, facilitando a troca entre aplicações especiais.

Tecnologia inovadora de 'Desenvolvimento Vertical de Toner'

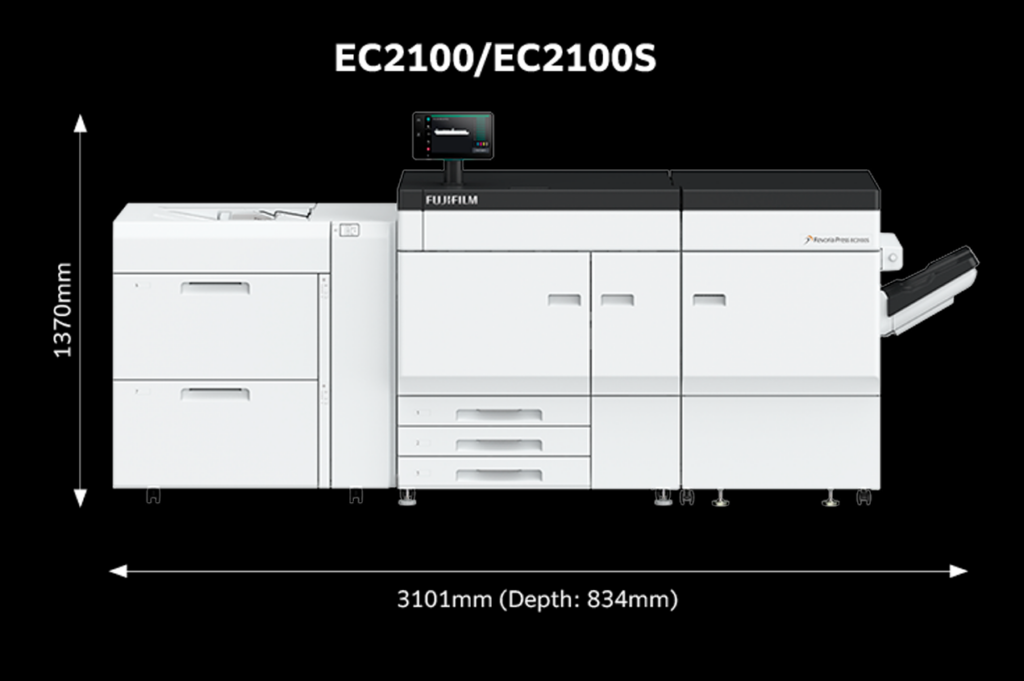

A eficiência de espaço é um fator crucial para muitas empresas, e a Fujifilm resolveu esse problema com sua tecnologia de "Desenvolvimento Vertical de Toner". Essa inovação permite a integração de cinco estações de cores sem aumentar o espaço total da máquina, tornando essas impressoras a escolha ideal para ambientes com espaço limitado. Ao contrário das unidades de desenvolvimento horizontal convencionais, este design inovador empilha o suprimento de toner verticalmente, reduzindo significativamente o espaço ocupado pela máquina.

Além da economia de espaço, essa tecnologia também melhora a estabilidade da transferência de toner, resultando em uma qualidade de impressão mais consistente em diferentes tipos de mídia. A redução da complexidade interna também se traduz em menos peças móveis, reduzindo a necessidade de manutenção e aumentando a longevidade geral da máquina.

Qualidade

Como qualquer máquina Fujifilm, estas novas impressoras de gama média destacam-se pela qualidade alcançada. Além do canal de cores adicional, existem diversos desenvolvimentos tecnológicos que garantem uma qualidade de impressão excecional, mesmo em quatro cores. Todos os quatro modelos utilizam uma cabeça de impressão LED de 2.400 x 2.400 dpi para detalhes nítidos e gradientes suaves. Esta avançada tecnologia LED garante texto nítido, linhas finas e imagens cristalinas, além dos benefícios de maior longevidade e menor consumo de energia, melhorando o desempenho sustentável das impressoras.

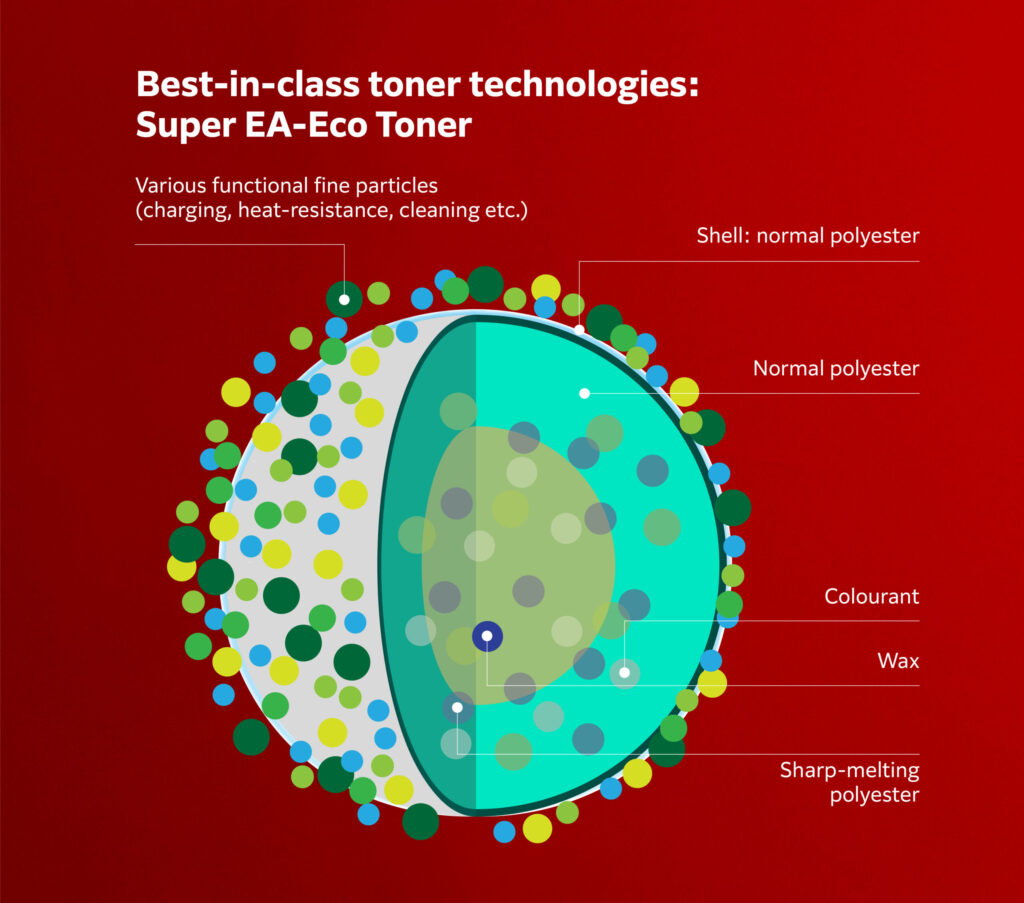

O uso do toner Super EA-Eco do Fujifilm, utilizando os menores tamanhos de partículas do setor, contribui para nitidez de imagem superior, granulação reduzida e transições tonais perfeitas.

Além disso, todas as impressoras utilizam o processamento de profundidade de cor de 10 bits da Fujifilm. Enquanto a maioria dos concorrentes normalmente utiliza a tecnologia de 8 bits, que captura apenas 256 níveis por canal de cor, os modelos Revoria elevam essa tecnologia para 1.024 níveis por canal, melhorando significativamente a precisão tonal e a fidelidade das cores. Isso proporciona uma qualidade de impressão excepcional, especialmente para aplicações de ponta que exigem um alto grau de precisão.

Todas as impressoras desta linha utilizam o novo recurso Smart Monitoring Gate da Fujifilm – um sistema automatizado de controle de qualidade que garante estabilidade de impressão, registro preciso de frente para trás e precisão de cores consistente durante toda a produção. Ao fazer ajustes em tempo real, essa tecnologia ajuda a reduzir o desperdício e maximizar a eficiência operacional.

Versatilidade

As tecnologias de alimentação de papel nas impressoras são de última geração. Tradicionalmente, os alimentadores de papel utilizam tecnologia de alimentação por fricção com rolos de borracha. Este sistema, com seus sopradores laterais e detector de alimentação múltipla, o torna ultraconfiável e eficaz.

Uma série de outras novas tecnologias nas impressoras também contribuem para torná-las uma das mais versáteis do mercado, capazes de suportar uma gama ampliada de aplicações. Elas podem lidar facilmente com uma variedade de substratos desafiadores, como mídias texturizadas e em relevo. Envelopes e impressões de pequeno formato são facilmente acomodados graças a um mecanismo de alimentação de precisão, enquanto as impressoras também podem imprimir em mídias sintéticas e resistentes à água (como sinalização, etiquetas e materiais de marketing para exteriores). A impressão em folhas longas, graças à capacidade das impressoras de imprimir até 1.300 mm de comprimento, também está dentro das capacidades padrão.

Controle estático

As impressoras Revoria da Fujifilm podem acomodar uma ampla gama de tipos de mídia e, com muitos deles – como filme de camada única ou papel sintético, resistente à água ou adesivo –, cargas estáticas são um problema comum. Essas cargas indesejadas podem fazer com que as folhas grudem, causando atrasos na produção ou no acabamento.

Barras eliminadoras de estática raramente estão disponíveis em prensas POD de gama baixa ou média e, quando estão, costumam ser de qualidade bastante baixa e ineficazes na prevenção da ocorrência de tais cargas. As prensas Revoria SC285 e EC2100, por outro lado, têm a opção de instalar o mesmo módulo eliminador de estática usado na principal Revoria PC1120, oferecendo um nível de confiabilidade normalmente disponível apenas a um preço muito mais alto.

Desenrolador integrado e alimentador de sucção de ar

As impressoras também incluem um desenrolador integrado. Instalado diretamente após o fusor, o desenrolador elimina a deformação do papel causada pelo calor e pela pressão da unidade de fusão. Este sistema garante um transporte estável do papel, corrigindo mecanicamente a ondulação da folha (tanto para cima quanto para baixo), antes que o papel seja alimentado para o caminho de papel duplex ou para a bandeja de saída.

Adequado para todos os tipos de papel

Quando se trata de impressão em diferentes tipos de papel, um mecanismo de comutação de carga secundária de transferência Advanced Single Layer Belt (A-SLB) recentemente desenvolvido e a tecnologia de estabilização da condição do toner se combinam para melhorar substancialmente a transferência do toner para papel gofrado ou espesso. As melhorias nas tecnologias de formação e transferência de imagem, por sua vez, aprimoraram a qualidade de impressão em papel comum e áspero.

Além disso, a Fujifilm desenvolveu uma tecnologia de estabilização de campo elétrico de transferência ideal para cada tipo de papel, melhorando a capacidade de imprimir densidades uniformes, enquanto duas novas tecnologias de transferência de papel resultam em recursos de manuseio de papel líderes do setor para papéis grossos e envelopes.

A primeira dessas novas tecnologias é um mecanismo secundário de comutação de carga de transferência que ajusta automaticamente a pressão para segurar o papel de acordo com sua espessura. A segunda é um novo mecanismo de torque de transferência variável para estabilizar a alimentação do papel. Ambas as novas tecnologias permitem a impressão de papéis e envelopes espessos sem vincos e de forma consistente.

Para impressão em papel fino, por outro lado, o uso de um dispositivo de transferência do tipo correia, em vez de um dispositivo do tipo rolo, aumenta a precisão e a estabilidade e, ao imprimir cartões postais, o uso de um obturador para bloquear a área fora do caminho do papel melhora a estabilidade do manuseio na impressora.

Velocidade e produtividade

Além de cor, qualidade e versatilidade, as impressoras oferecem velocidade excepcional. Os modelos EC2100 e EC2100S operam a até 100 páginas por minuto (ppm) para A4 e 55 ppm para A3, enquanto as SC285 e SC285S atingem até 85 ppm (A4) e 47 ppm (A3). Essas velocidades são mantidas mesmo na impressão em mídias mais pesadas, com ambos os modelos suportando papéis de até 400 g/m². Isso as torna adequadas para uma variedade de aplicações, incluindo embalagens, cartões de visita e produtos de impressão premium que exigem durabilidade e acabamento de alta qualidade.

Automação

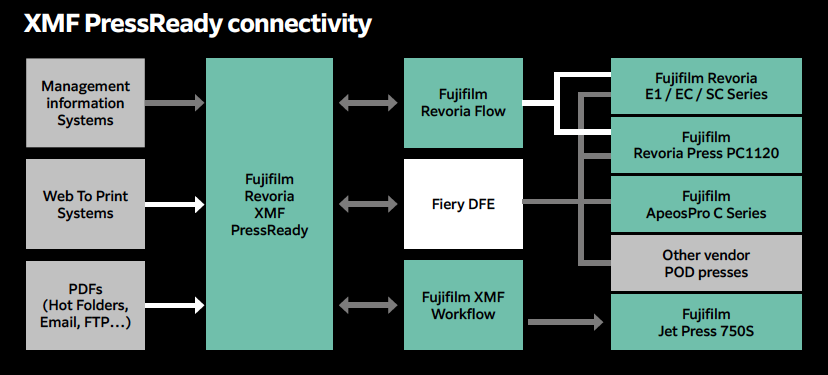

Todos os modelos são compatíveis com o servidor de impressão Revoria Flow da Fujifilm e com os controladores de impressão Fiery, oferecendo uma variedade de soluções de fluxo de trabalho flexíveis. Essas plataformas oferecem gerenciamento avançado de cores, ferramentas de automação e recursos de impressão de dados variáveis, garantindo uma integração perfeita com os ambientes de produção existentes. Para usuários que buscam ir ainda mais longe na automação, o sistema de fluxo de trabalho de produção de impressão digital XMF PressReady da Fujifilm recebe, pré-processa, impõe, agrupa, classifica e entrega trabalhos "Prontos para Impressão" usando fluxos de produção automatizados. Ele é compatível com as soluções de fluxo de trabalho Revoria Flow e Fiery, permitindo que os usuários automatizem tarefas repetitivas e liberem o tempo dos operadores de impressão para que se concentrem em aspectos mais importantes do processo de produção.

Todos os modelos são compatíveis com o servidor de impressão Revoria Flow da Fujifilm e com os controladores de impressão Fiery, oferecendo uma variedade de soluções de fluxo de trabalho flexíveis. Essas plataformas oferecem gerenciamento avançado de cores, ferramentas de automação e recursos de impressão de dados variáveis, garantindo uma integração perfeita com os ambientes de produção existentes. Para usuários que buscam ir ainda mais longe na automação, o sistema de fluxo de trabalho de produção de impressão digital XMF PressReady da Fujifilm recebe, pré-processa, impõe, agrupa, classifica e entrega trabalhos "Prontos para Impressão" usando fluxos de produção automatizados. Ele é compatível com as soluções de fluxo de trabalho Revoria Flow e Fiery, permitindo que os usuários automatizem tarefas repetitivas e liberem o tempo dos operadores de impressão para que se concentrem em aspectos mais importantes do processo de produção.

Sustentabilidade

A sustentabilidade é um requisito fundamental para uma solução de produção de impressão moderna e avançada e continua sendo o cerne dos valores da Fujifilm. Essas quatro impressoras não são diferentes em atender a essas expectativas. A cabeça de impressão LED e o toner Super EA-Eco operam em temperaturas de fusão mais baixas, devido ao ponto de fusão ultrabaixo do toner, reduzindo assim o consumo de energia. Além disso, o mecanismo de alimentação por sucção de ar minimiza atolamentos e falhas de alimentação de papel, melhorando a eficiência e reduzindo o desperdício de material. Por fim, as aplicações impressas nessas impressoras, e em todas as impressoras da linha Revoria, são totalmente recicláveis. Para comprovar isso, a Fujifilm obteve a acreditação INGEDE, para certificar que os produtos impressos nas impressoras Revoria são destintáveis e totalmente recicláveis nos fluxos padrão de reciclagem de papel.

Tornando o extraordinário, ordinário

As tecnologias mais recentes incorporadas ao portfólio de impressoras POD da Fujifilm são um exemplo poderoso da capacidade da empresa de inovar – não apenas para expandir os limites do que é possível alcançar com impressoras de toner – mas também para adaptá-las de forma que sejam acessíveis ao maior público possível. As tecnologias de ponta que a Fujifilm traz ao mercado hoje se tornarão o padrão mínimo esperado amanhã, à medida que o ritmo das mudanças tecnológicas continua a aumentar.