Inteligentní monitorovací brána Fujifilm

Role „inteligentního monitorování“

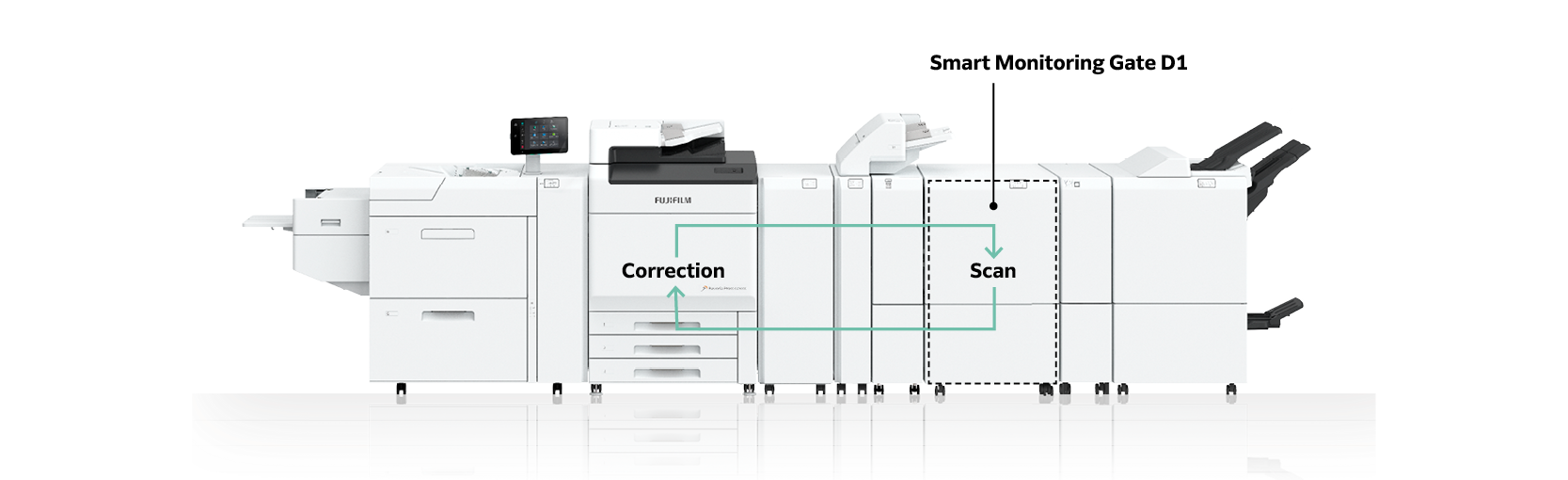

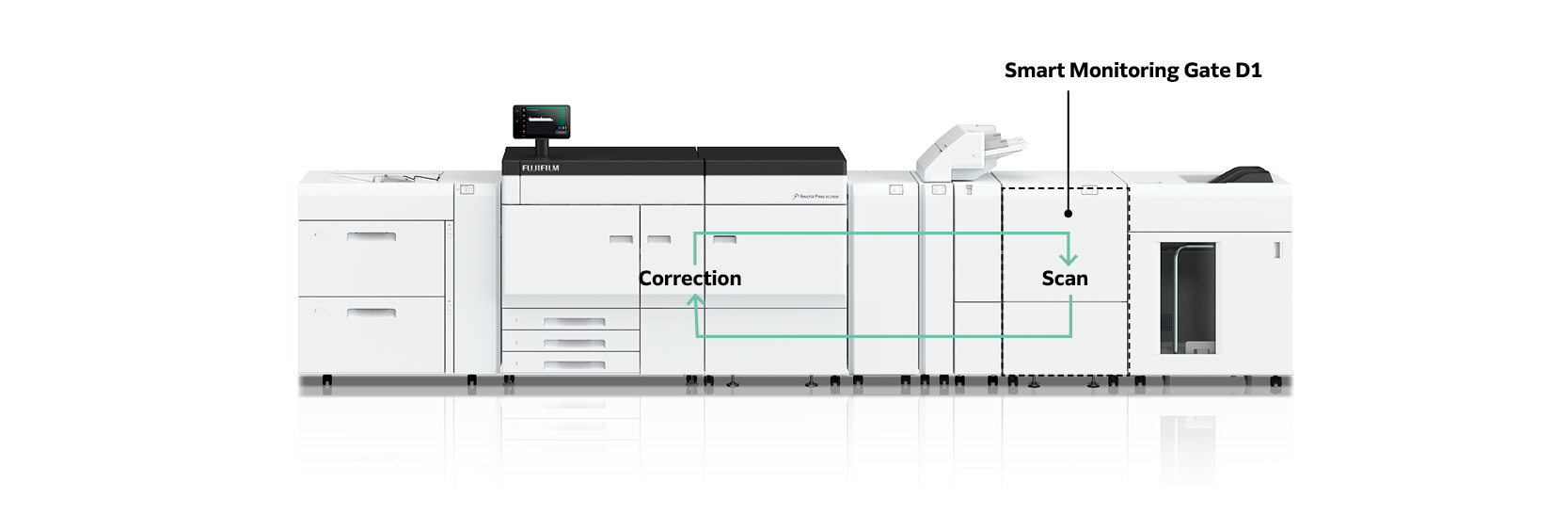

Inteligentní monitorovací brána (Smart Monitoring Gate) je umístěna vně tonerové tiskové jednotky, kde papír vychladl a stabilizoval se do svého přirozeného stavu. To je záměrné, protože papír může být uvnitř tiskového stroje stále horký, což vede k jeho roztahování a zkreslení naměřených hodnot. Umístěním modulu vně odrážejí měření skutečný, konečný stav tisku.

Dva strategicky umístěné skenery, jeden nad a jeden pod archem, nepřetržitě monitorují soutisk i konzistenci barev od přední k zadní straně. Systém automaticky tiskne čtyři barevné plochy podél okrajů a v rozích každého archu vyřízne malé křížky. Tyto značky poskytují senzorům jasné referenční body pro měření soutisku a barev a vyžadují malý okraj, který nemusí být vhodný pro skutečný tisk od okraje k okraji.

Pokud je zjištěna odchylka, systém okamžitě komunikuje se strojem a provádí jemné úpravy, aby se zabránilo chybám dříve, než k nim dojde. U krátkých zakázek se to nemusí zdát kritické, protože stroj může dokončit tisk dříve, než se projeví jakákoli odchylka. U delších zakázek, kde se teplota a vlhkost v místnosti mohou v průběhu času měnit, však tento systém tiše udržuje vše v souladu. To znamená méně zásahů, méně chyb a mnohem menší riziko pozdního odhalení problémů.

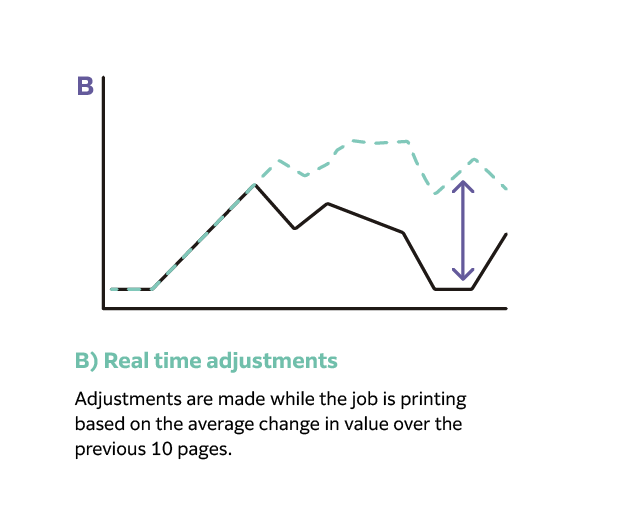

Chytré úpravy bez nadměrné korekce

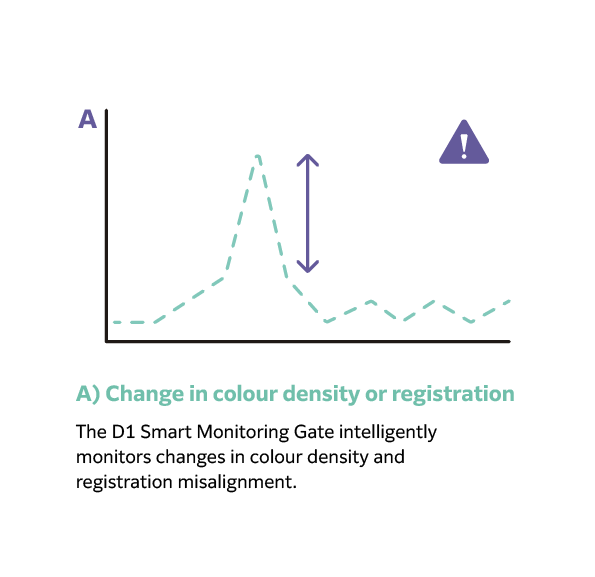

Modul nereaguje na každou drobnou odchylku. Aby se zabránilo nadměrné korekci, vypočítává průměry z posledních deseti vytištěných listů. Například pouze tehdy, když odchylka překročí přednastavenou prahovou hodnotu, spustí upozornění, které buď informuje obsluhu, nebo pozastaví úlohu, v závislosti na nastavení, ale upozornění spustí pouze tehdy, když dojde k drastické odchylce. To umožňuje plynulé a postupné úpravy, které zajistí stabilní a konzistentní kvalitu tisku bez nežádoucích výkyvů.

Bližší pohled na technologii

Inteligentní monitorovací brána zvládá širokou škálu formátů papíru a dokáže zpracovávat papír o gramáži od 52 do 400 g/m² bez přerušení provozu. To vše běží na pozadí, aniž by to přerušovalo výrobu nebo zpomalovalo tiskový stroj. A navzdory svým možnostem je samotný modul kompaktní a energeticky úsporný. Je navržen pro prostředí s vysokým objemem tisku, je zkonstruován tak, aby rozpoznal, co by lidské oko mohlo přehlédnout, a je navržen tak, aby to dělal bez překážek.

Automatizace: vyšší produktivita a méně odpadu

Inteligentní monitorovací brána přináší výrazné zvýšení produktivity tím, že přebírá úkol, který tradičně vyžadoval značný čas operátora. Operátoři často stráví manuální kontrolou výstupu v každém cyklu přibližně 3 minuty. Automatizací tohoto klíčového kroku kontroly kvality inteligentní monitorovací brána snižuje počet manuálních kontrol a šetří čas, pomáhá týmům přesunout pozornost od rutinní kontroly k hodnotnějším úkolům a zvyšuje celkovou produktivitu.

A protože systém detekuje problémy s registrací a konzistencí barev již v rané fázi tiskového procesu, méně archů se plýtvá a spotřebovává se méně inkoustu. Výsledkem je jednodušší, nákladově efektivnější a udržitelnější přístup k tisku. Důležité je, že inteligentní monitorovací brána provádí měření a korekce za chodu, takže rychlost tisku zůstává prakticky nezměněna.

Řešení obav

Je přirozené, že si zákazníci kladou otázku: „Pokud je potřeba korekční systém, je tiskový stroj skutečně stabilní?“ Odpověď zní ano. Tiskové stroje Revoria jsou navrženy pro konzistenci. Proměnné prostředí jsou však reálné a při dlouhých sériích se mohou sčítat.

Tento modul slouží jako proaktivní opatření k udržení nejvyšších standardů kvality, zejména při delších tiskových sériích, kde se u jakéhokoli tiskového systému mohou vyskytnout drobné odchylky. Je to nástroj, který zajišťuje konzistentní výstup a dodává další vrstvu jistoty.

Pohled do budoucna

Současný modul se zaměřuje na registraci a barvy, ale vize Fujifilm pro kvalitu tisku sahá ještě dále. Verze nové generace, která je již dostupná v Japonsku, zavádí kontrolu celého archu, která je schopna detekovat vrásky, skvrny, vlákna a další vady za okraji.

Inteligentní monitorovací brána tiskárny Fujifilm je cenným přínosem pro každého poskytovatele tiskových služeb, který chce optimalizovat provoz a dosahovat konzistentně vysoce kvalitních výsledků. Minimalizuje odpad, maximalizuje efektivitu a poskytuje zákazníkům klid, že jejich výtisky budou pokaždé perfektní.